Calculating Activity Amounts for Production and Process Orders with SAP ABAP

Posted on January 3, 2018

Edit June 1st, 2018:

There was ANOTHER issue with this code! There is something you need to add if you want to book custom goods movements for the retrograde materials. You can see how to do this in footnote 6 for more.

Edit April 19th, 2018:

There was a bug with this code! When we make the conversion to MIN, we forgot to overwrite lv_unit to MIN, so the conversion was correct, but the unit was left in hours, or H ! You can see this in the code comments with date 2018.04.19.

First off, Congratulations! :confetti_ball:

And a happy new year! (If you're viewing this in the summer or something, see the date! 😉)You've found the only post on the entire internet that describes the full process of calculating activity amounts for production order confirmations by programming it directly using SAP ABAP! :scream::scream::scream:

I hope you use this post to maximum effectiveness, because it took me four days to find, build, and get a working answer. 😊

The Problem

Let's jump right into ABAP programming: the go-to function module to calculate time ticket proposals for production orders is with function module BAPI_PRODORDCONF_GET_TT_PROP:

CALL FUNCTION 'BAPI_PRODORDCONF_GET_TT_PROP'

* EXPORTING

* PROPOSE = ' '

* IMPORTING

* RETURN =

TABLES

timetickets =

* GOODSMOVEMENTS =

* LINK_CONF_GOODSMOV =

* DETAIL_RETURN =

.

Likewise, there is a very similiar BAPI_PROCORDCONF_GET_TT_PROP for process orders:

CALL FUNCTION 'BAPI_PROCORDCONF_GET_TT_PROP'

* EXPORTING

* PROPOSE = ' '

* IMPORTING

* RETURN =

TABLES

timetickets =

* GOODSMOVEMENTS =

* LINK_CONF_GOODSMOV =

* DETAIL_RETURN =

.

Pretty similar. However, as part of my indentured servitude that is being a full-time employee, I spent a day tinkering, writing, and testing code with these function modules. No matter what combinations of inputs I provided, I couldn't get the activity confirmation amount to be calculated, which are a very important part of the final calculation of the confirmation! (more on the actual final confirmation submission is also included in later on) From scrounging around on SCN and the SAP blog, I learned that many developers had the same issue with these functions. (Things like date, yield/scrap amounts, and the goods movements would be proposed just fine by these BAPIs.)

So, calculating these activity confirmation amounts programmatically (in ABAP) will be the main focus of this post 1.

Unfortunately, with much more digging, the reason the two functions wouldn't produce activity confirmation amounts never became quite clear to me. I realized I would have to calculate them in a more manual manner and then add them to those BAPI structures lt_timetickets manually.

The Calculation Function Module

Through SAP GUI in transaction CO11N, determining system-proposed confirmation amounts is easy enough by and asking the system to do the calculation for us 2. My struggle was finding the programmatic way to do this in ABAP.

Anyone with significant production planning experience (i.e., not me 😂 ) knows that the actual formula behind the activity calculation is not with the activity itself, but with the work center behind the activity 3.

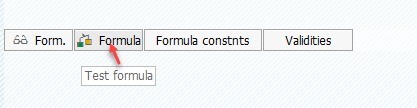

In transaction CR03 (display work center), in the 'Costing' Tab, there is a 'Formula' button with the check symbol on it:

This was my starting point to find any sort of function that could do this programmatically - with more time, I learned from SCN of a function that does exactly that! It's called CR_WORKCENTER_FORMULA_CALC!

Let's head on over to transaction SE37 and test it ourselves!

:expressionless::expressionless::expressionless: shit... SAP, you had one job to do!

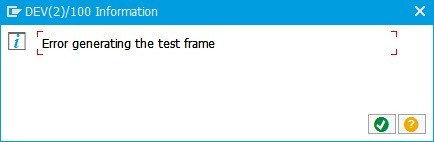

Fine. We'll do it ourselves. We can open up the source code of CR_WORKCENTER_FORMULA_CALC and set a breakpoint in the first line:

and in CR03, drag our debugging shortcut into the calculation window, and we press return SAP debugging's return button to jump out to whatever parent program is calling this function...  and...

and...

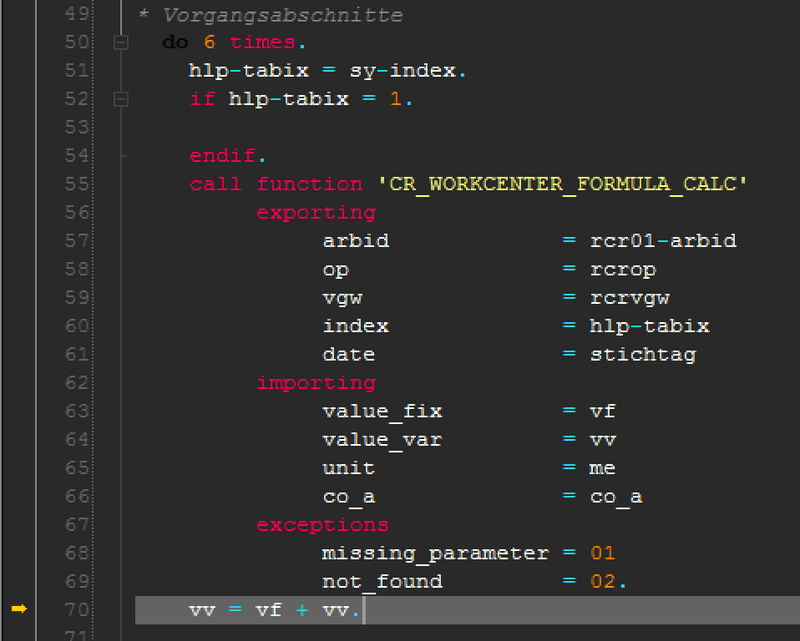

:pray: Violá! :pray: We've found where CR_WORKCENTER_FORMULA_CALC is called out in the wild!

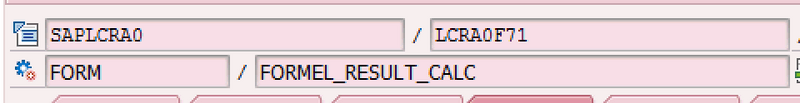

(For those deeply interested, you can find exactly where the function is called in SAP Program SAPLCRA0, Include LCRA0F71, line 55, at least for SAPGUI 740.)

The Details (The Hard Part)

So what the heck does SAP do with this function? Well, first, they are doing a do loop six times. Aha, we know why - because there can be a total of six confirmation values 4 - SAP is by default looping over all of them.

Now for the function parameters themselves: they pass the work center code (arbid), the operation number (rcrop), the index of the confirmation (a value of 1-6), our 4 default values (vgw), and the date (date).

In turn, the function spits out the fixed value amount of the activity calculation (value_fix), the variable part (value_var), both in whatever unit the function gives out in unit, and co_a is for the cost center accounting 5. There are actually four exceptions to this function, so I'm not sure why SAP internal is taking only two of them. In any case, there are other IMPORTING and EXPORTING parameters in the function signature, but this looks like a good starting point as a minimum. In fact, as you'll see below, the final working version of the code I created is almost exactly the same except where I found out with a bit of playing around.

So I mentioned the default values that must go into vgw - these are the four values that are the equivalent of those four fields we can type into in COR3 for checking the formula, things like setup time, machine time, personnel setup, and personnel time. It might sound like a lot of work to hunt down these values, but luckily these are master data and can be determined with a few select statements, first from table AFVC 'operation within an order', and then table PLPO 'task list - operation/activity':

" this is the full key for table AFVC - operation within an order - for the routing number and counter - should always work with SELECT SINGLE

SELECT SINGLE * FROM afvc INTO ls_afvc

WHERE aufpl = ls_operation-routing_no

AND aplzl = ls_operation-counter.

" this is the full key for table PLPO - task list - operation/activity - so it should always work with SELECT SINGLE

SELECT SINGLE * FROM plpo INTO ls_plpo

WHERE plnty EQ ls_afvc-plnty

AND plnnr EQ ls_afvc-plnnr

AND plnkn EQ ls_afvc-plnkn

AND zaehl EQ ls_afvc-zaehl.

The routing number ls_operation-routing_no and counter ls_operation-counter we've gotten from function BAPI_PRODORD_GET_DETAIL:

" need only the operations from the function

ls_order_objects-operations = 'X'.

lv_number = ls_orderid_so-low.

CALL FUNCTION 'BAPI_PRODORD_GET_DETAIL'

EXPORTING

number = lv_number

* COLLECTIVE_ORDER =

order_objects = ls_order_objects

* IMPORTING

* RETURN =

TABLES

* HEADER =

* POSITION =

* SEQUENCE =

operation = lt_operation

* TRIGGER_POINT =

* COMPONENT =

* PROD_REL_TOOL =

.

(There is plenty of SAP standard documentation and discussion on SCN on how to use BAPI_PRODORD_GET_DETAIL, so I'll leave that to you if you need more info 😉. Here we are just getting the operation information from the order - that's all we need.)

We can finally move the corresponding fields of ls_plpo to ls_vgw:

MOVE-CORRESPONDING ls_plpo TO ls_vgw.

However, in addition to these four values, there are two more that are essential, that is the yield amount (mgvrg), and the unit (meinh)! We can pass them right into ls_op as well:

MOVE-CORRESPONDING ls_plpo TO ls_op.

ls_op-mgvrg = ls_yield_so-low.

ls_op-meinh = ls_conf_quan_unit_so-low.

Armed with our structures ls_afvc, ls_op, and ls_vgw, we are ready to call our function:

CALL FUNCTION 'CR_WORKCENTER_FORMULA_CALC' " You can see a SAP standard example with the function in the source code for transaction CR03 for costing formula: Program SAPLCRA0, Include LCRA0F71, Form FORMEL_RESULT_CALC, line 55

EXPORTING

arbid = ls_afvc-arbid

op = ls_op

vgw = ls_vgw

index = sy-index

date = sy-datum

IMPORTING

value_fix = lv_value_fix

value_var = lv_value_var

unit = lv_unit

EXCEPTIONS

missing_parameter = 1

not_found = 2

division_by_zero = 3

OTHERS = 4.

IF sy-subrc <> 0.

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

We want the total, right? Okay, we just add the fixed value and variable value part:

lv_value = lv_value_fix + lv_value_var. " total value is the sum of the fixed and variable values for this activity

A requirement by my company was to have all the activity confirmation values with the same unit (I find it cleaner anyway to have all the activity confirmation values in the same unit anyway). Unfortunately, the default unit for some of the activities was hours, so we have to take a small intermediary step and call a conversion function before we are truly done:

" convert any 'H' values to 'MIN'

IF lv_unit NE 'MIN'.

CALL FUNCTION 'UNIT_CONVERSION_SIMPLE'

EXPORTING

input = lv_value

unit_in = lv_unit

unit_out = 'MIN'

IMPORTING

output = lv_output

EXCEPTIONS

conversion_not_found = 1

division_by_zero = 2

input_invalid = 3

output_invalid = 4

overflow = 5

type_invalid = 6

units_missing = 7

unit_in_not_found = 8

unit_out_not_found = 9

OTHERS = 10.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

We then finally carry over this converted lv_output over to the conf_activity field for lt_timetickets, doing this for all 1-6 conf_activity's:

CASE sy-index.

WHEN 1.

ls_timetickets-conf_activity1 = lv_output.

ls_timetickets-conf_acti_unit1 = 'MIN'.

WHEN 2.

ls_timetickets-conf_activity2 = lv_output.

ls_timetickets-conf_acti_unit2 = 'MIN'.

WHEN 3.

ls_timetickets-conf_activity3 = lv_output.

ls_timetickets-conf_acti_unit3 = 'MIN'.

WHEN 4.

ls_timetickets-conf_activity4 = lv_output.

ls_timetickets-conf_acti_unit4 = 'MIN'.

WHEN 5.

ls_timetickets-conf_activity5 = lv_output.

ls_timetickets-conf_acti_unit5 = 'MIN'.

WHEN 6.

ls_timetickets-conf_activity6 = lv_output.

ls_timetickets-conf_acti_unit6 = 'MIN'.

ENDCASE.

With that, we can call the final confirmation function, with all our calculated values wrapped up in lt_timetickets:

" create confirmation

CALL FUNCTION 'BAPI_PRODORDCONF_CREATE_TT'

* EXPORTING

* POST_WRONG_ENTRIES = '0'

* TESTRUN =

* CALL_ON_INBOUND_QUEUE = ' '

IMPORTING

return = ls_return

TABLES

timetickets = lt_timetickets

goodsmovements = lt_goodsmovements

* LINK_CONF_GOODSMOV =

* CHARACTERISTICS_WIPBATCH =

* LINK_CONF_CHAR_WIPBATCH =

detail_return = lt_detail_return

* CHARACTERISTICS_BATCH =

* LINK_GM_CHAR_BATCH =

EXCEPTIONS

OTHERS = 1.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

If you were sharp, you realized all of this code is only on the operation level - so indeed, the six-level loop must be done each time, for each operation - we have to throw all the above code into a loop over our operations! See below for the full result!

Production Orders

In summary, the full code looks like this:

NOTE: the full code examples were written for a SAP Gateway environment - i.e. the server environment from a SAPUI5 OData call! If you try to copy and paste this code directly into something like a report or function, ABAP statements like:

lt_filters = io_tech_request_context->get_filter( )->get_filter_select_options( ).

won't be in scope and won't compile without errors! However, if you are familiar with the CRUD based methods of the SAP Gateway backend, these will fit nicely into the GET_ENTITYSET method 😊

DATA : lt_filters TYPE /iwbep/t_mgw_select_option,

ls_filters LIKE LINE OF lt_filters,

lt_select_options TYPE TABLE OF /iwbep/s_cod_select_option,

ls_plant_so LIKE LINE OF lt_select_options,

ls_orderid_so LIKE LINE OF lt_select_options,

ls_fin_conf_so LIKE LINE OF lt_select_options,

ls_dev_reason_so LIKE LINE OF lt_select_options,

ls_conf_text_so LIKE LINE OF lt_select_options,

ls_conf_quan_unit_so LIKE LINE OF lt_select_options,

ls_yield_so LIKE LINE OF lt_select_options,

ls_scrap_so LIKE LINE OF lt_select_options,

lt_stg_loc TYPE TABLE OF /iwbep/s_cod_select_option,

ls_stg_loc LIKE LINE OF lt_stg_loc,

lt_batch TYPE TABLE OF /iwbep/s_cod_select_option,

ls_batch LIKE LINE OF lt_batch,

lt_reserv_no TYPE TABLE OF /iwbep/s_cod_select_option,

ls_reserv_no LIKE LINE OF lt_reserv_no,

lt_res_item TYPE TABLE OF /iwbep/s_cod_select_option,

ls_res_item LIKE LINE OF lt_res_item,

lt_entry_qnt TYPE TABLE OF /iwbep/s_cod_select_option,

ls_entry_qnt LIKE LINE OF lt_entry_qnt,

lt_entry_uom TYPE TABLE OF /iwbep/s_cod_select_option,

ls_entry_uom LIKE LINE OF lt_entry_uom,

ls_return TYPE bapiret1,

lt_goodsmovements TYPE TABLE OF bapi2017_gm_item_create,

ls_goodsmovements LIKE LINE OF lt_goodsmovements,

lv_reserv_lines TYPE int4,

lv_index TYPE int4 VALUE 1,

lt_detail_return TYPE TABLE OF bapi_coru_return,

ls_detail_return LIKE LINE OF lt_detail_return,

lv_log_handle TYPE balloghndl,

lv_message TYPE char200,

lo_logger TYPE REF TO zcl_bc_app_logger,

es_entityset LIKE LINE OF et_entityset,

lv_error_message TYPE bapi_msg,

ls_order_objects TYPE bapi_pp_order_objects,

lt_operation TYPE TABLE OF bapi_order_operation1,

ls_operation LIKE LINE OF lt_operation,

lt_timetickets TYPE TABLE OF bapi_pp_timeticket,

ls_timetickets LIKE LINE OF lt_timetickets,

lv_number TYPE bapi_order_key-order_number,

ls_propose TYPE bapi_pp_conf_prop,

ls_op TYPE rcrop,

ls_vgw TYPE rcrvgw,

ls_afvc TYPE afvc,

ls_plpo TYPE plpo,

lv_value_fix TYPE p DECIMALS 4,

lv_value_var TYPE p DECIMALS 4,

lv_value TYPE p DECIMALS 4,

lv_unit TYPE rcrvgw-vge01,

lv_output TYPE p DECIMALS 3.

" Create a log instance

CREATE OBJECT lo_logger

EXPORTING

iv_subobject = 'ZPP_APP'.

lo_logger->create_log( IMPORTING ev_log_handle = lv_log_handle ).

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = 'Begin Method PRODCONFIRMATION_GET_ENTITYSET.' ). " add custom message to message log

"get $filter through the io_tech request (odata request)

lt_filters = io_tech_request_context->get_filter( )->get_filter_select_options( ).

" Process filters

" for these below we just need the singular select option structure

READ TABLE lt_filters WITH TABLE KEY property = 'PLANT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_plant_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ORDERID' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_orderid_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'FIN_CONF' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_fin_conf_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'DEV_REASON' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_dev_reason_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'CONF_TEXT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_conf_text_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'CONF_QUAN_UNIT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_conf_quan_unit_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'YIELD' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_yield_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'SCRAP' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_scrap_so INDEX 1.

" for the following we need tables (make a loop and get the values from each)

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'STGE_LOC' INTO ls_filters.

lt_stg_loc = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'BATCH' INTO ls_filters.

lt_batch = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'RESERV_NO' INTO ls_filters.

lt_reserv_no = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'RES_ITEM' INTO ls_filters.

lt_res_item = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ENTRY_QNT' INTO ls_filters.

lt_entry_qnt = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ENTRY_UOM' INTO ls_filters.

lt_entry_uom = ls_filters-select_options.

" Create goodsmovement structure for all the retroactive items

DESCRIBE TABLE lt_reserv_no LINES lv_reserv_lines.

DO lv_reserv_lines TIMES.

ls_stg_loc = lt_stg_loc[ lv_index ].

ls_batch = lt_batch[ lv_index ].

ls_reserv_no = lt_reserv_no[ lv_index ].

ls_res_item = lt_res_item[ lv_index ].

ls_entry_qnt = lt_entry_qnt[ lv_index ].

ls_entry_uom = lt_entry_uom[ lv_index ].

ls_goodsmovements-plant = ls_plant_so-low. " fixed factory

ls_goodsmovements-stge_loc = ls_stg_loc-low.

ls_goodsmovements-batch = ls_batch-low.

ls_goodsmovements-move_type = '261'. " fixed movement type

ls_goodsmovements-item_text = 'Warenbewegung für Rückmeldung PP APP'.

ls_goodsmovements-reserv_no = ls_reserv_no-low.

ls_goodsmovements-res_item = ls_res_item-low.

ls_goodsmovements-entry_qnt = ls_entry_qnt-low.

ls_goodsmovements-entry_uom = ls_entry_uom-low.

APPEND ls_goodsmovements TO lt_goodsmovements.

lv_index = lv_index + 1.

ENDDO.

" need only the operations from the function

ls_order_objects-operations = 'X'.

lv_number = ls_orderid_so-low.

CALL FUNCTION 'BAPI_PRODORD_GET_DETAIL'

EXPORTING

number = lv_number

* COLLECTIVE_ORDER =

order_objects = ls_order_objects

* IMPORTING

* RETURN =

TABLES

* HEADER =

* POSITION =

* SEQUENCE =

operation = lt_operation

* TRIGGER_POINT =

* COMPONENT =

* PROD_REL_TOOL =

.

" build structures for each step (each operation)

LOOP AT lt_operation INTO ls_operation.

CLEAR ls_timetickets.

" this is the full key for table AFVC - Auftragsarbeitsvorgang for the routing number and counter - should always work with SELECT SINGLE

SELECT SINGLE * FROM afvc INTO ls_afvc

WHERE aufpl = ls_operation-routing_no

AND aplzl = ls_operation-counter.

" this is the full key for table PLPO - Plan: Vorgang - so it should always work with SELECT SINGLE

SELECT SINGLE * FROM plpo INTO ls_plpo

WHERE plnty EQ ls_afvc-plnty

AND plnnr EQ ls_afvc-plnnr

AND plnkn EQ ls_afvc-plnkn

AND zaehl EQ ls_afvc-zaehl.

" now provide all the standard values (vorgabewert) VGW01, 02, etc into the calculation formula

MOVE-CORRESPONDING ls_plpo TO ls_op.

ls_op-mgvrg = ls_yield_so-low.

ls_op-meinh = ls_conf_quan_unit_so-low.

MOVE-CORRESPONDING ls_plpo TO ls_vgw.

DO 6 TIMES. " for each activity (usually 4 activities here at my company, but there can be up to 6 activities total)

IF sy-index EQ 1 AND ls_vgw-vgw01 EQ 0

OR sy-index EQ 2 AND ls_vgw-vgw02 EQ 0

OR sy-index EQ 3 AND ls_vgw-vgw03 EQ 0

OR sy-index EQ 4 AND ls_vgw-vgw04 EQ 0f

OR sy-index EQ 5 AND ls_vgw-vgw05 EQ 0

OR sy-index EQ 6 AND ls_vgw-vgw06 EQ 0.

CONTINUE. " skip and 0 values

ENDIF.

CALL FUNCTION 'CR_WORKCENTER_FORMULA_CALC' " You can see a SAP standard example with the function in the source code for transaction CR03 for costing formula: Program SAPLCRA0, Include LCRA0F71, Form FORMEL_RESULT_CALC, line 55

EXPORTING

arbid = ls_afvc-arbid

op = ls_op

vgw = ls_vgw

index = sy-index

date = sy-datum

IMPORTING

value_fix = lv_value_fix

value_var = lv_value_var

unit = lv_unit

EXCEPTIONS

missing_parameter = 1

not_found = 2

division_by_zero = 3

OTHERS = 4.

IF sy-subrc <> 0.

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

lv_value = lv_value_fix + lv_value_var. " total value is the sum of the fixed and varible values for this activity

" convert any 'H' values to 'MIN'

IF lv_unit NE 'MIN'.

CALL FUNCTION 'UNIT_CONVERSION_SIMPLE'

EXPORTING

input = lv_value

unit_in = lv_unit

unit_out = 'MIN'

IMPORTING

output = lv_output

EXCEPTIONS

conversion_not_found = 1

division_by_zero = 2

input_invalid = 3

output_invalid = 4

overflow = 5

type_invalid = 6

units_missing = 7

unit_in_not_found = 8

unit_out_not_found = 9

OTHERS = 10.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

lv_unit = 'MIN'. " 2018.04.19 - need to overwrite unit to MIN!

ELSE.

lv_output = lv_value. " copy over MIN value

ENDIF.

CASE sy-index.

WHEN 1.

ls_timetickets-conf_activity1 = lv_output.

ls_timetickets-conf_acti_unit1 = 'MIN'.

WHEN 2.

ls_timetickets-conf_activity2 = lv_output.

ls_timetickets-conf_acti_unit2 = 'MIN'.

WHEN 3.

ls_timetickets-conf_activity3 = lv_output.

ls_timetickets-conf_acti_unit3 = 'MIN'.

WHEN 4.

ls_timetickets-conf_activity4 = lv_output.

ls_timetickets-conf_acti_unit4 = 'MIN'.

WHEN 5.

ls_timetickets-conf_activity5 = lv_output.

ls_timetickets-conf_acti_unit5 = 'MIN'.

WHEN 6.

ls_timetickets-conf_activity6 = lv_output.

ls_timetickets-conf_acti_unit6 = 'MIN'.

ENDCASE.

ENDDO.

" Now build the table to confirm the operations (Vorgänge)

ls_timetickets-conf_no = ls_operation-conf_no.

ls_timetickets-orderid = ls_orderid_so-low.

ls_timetickets-sequence = ls_operation-sequence_no.

ls_timetickets-operation = ls_operation-operation_number.

ls_timetickets-work_cntr = ls_operation-work_center. " Resource for process order, logdate, logtime, and posting date added to the table

ls_timetickets-plant = ls_plant_so-low.

ls_timetickets-logdate = sy-datlo.

ls_timetickets-logtime = sy-timlo.

ls_timetickets-postg_date = sy-datlo.

ls_timetickets-yield = ls_yield_so-low.

ls_timetickets-scrap = ls_scrap_so-low.

ls_timetickets-fin_conf = ls_fin_conf_so-low. " also overwrite the proposed partial or final confirmation - take what the user provides!

ls_timetickets-conf_quan_unit = ls_conf_quan_unit_so-low. " Also the unit

APPEND ls_timetickets TO lt_timetickets.

ENDLOOP.

" create confirmation

CALL FUNCTION 'BAPI_PRODORDCONF_CREATE_TT'

* EXPORTING

* POST_WRONG_ENTRIES = '0'

* TESTRUN =

* CALL_ON_INBOUND_QUEUE = ' '

IMPORTING

return = ls_return

TABLES

timetickets = lt_timetickets

goodsmovements = lt_goodsmovements

* LINK_CONF_GOODSMOV =

* CHARACTERISTICS_WIPBATCH =

* LINK_CONF_CHAR_WIPBATCH =

detail_return = lt_detail_return

* CHARACTERISTICS_BATCH =

* LINK_GM_CHAR_BATCH =

EXCEPTIONS

OTHERS = 1.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

Process Orders

Because SAP is ever-so-special, process orders have a slightly different program process due to a few name changes. Here is a summary of some of those name and type changes:

| Topic | Production Orders | Process Orders |

| ------- | ----------------- | -------------- |

| Name of the 'steps' in your process or production order | phase/activity (I've seen both names, ABAP uses mostly 'phase') | operation |

| Get order detail of order | BAPI_PRODORD_GET_DETAIL | BAPI_PROCORD_GET_DETAIL |

| detail of order 'step' type | bapi_order_phase | bapi_order_operation1 |

| Function for timeticket proposals | BAPI_PRODORD_GET_DETAIL | BAPI_PROCORD_GET_DETAIL |

| Function for order confirmation | BAPI_PRODORDCONF_CREATE_TT | BAPI_PROCORDCONF_CREATE_TT |

| timetickets TYPE in order confirmation function | bapi_pp_timeticket | bapi_pi_timeticket1 |

There are more, but you can find those in the code for yourself. The important thing to notice is that the key challenging part here, calculating the confirmation activity amounts, uses the same internal function module, ``

Here's the code for calculating activities for process orders - note the slight change in all the variable names! - and be careful with your types (carefully look over the DATA: statement), otherwise you'll get :boom:exploding runtime errors:boom: when you try to confirm something with one of our two main functions and you pass, for example, the lt_timetickets with the production type ``, and you pass it into the of the process order function module.

DATA : lt_filters TYPE /iwbep/t_mgw_select_option,

ls_filters LIKE LINE OF lt_filters,

lt_select_options TYPE TABLE OF /iwbep/s_cod_select_option,

ls_plant_so LIKE LINE OF lt_select_options,

ls_orderid_so LIKE LINE OF lt_select_options,

ls_fin_conf_so LIKE LINE OF lt_select_options,

ls_dev_reason_so LIKE LINE OF lt_select_options,

ls_conf_text_so LIKE LINE OF lt_select_options,

ls_conf_quan_unit_so LIKE LINE OF lt_select_options,

ls_yield_so LIKE LINE OF lt_select_options,

ls_scrap_so LIKE LINE OF lt_select_options,

ls_stge_loc_so LIKE LINE OF lt_select_options,

ls_batch_so LIKE LINE OF lt_select_options,

ls_reserv_no_so LIKE LINE OF lt_select_options,

ls_res_item_so LIKE LINE OF lt_select_options,

ls_entry_qnt_so LIKE LINE OF lt_select_options,

ls_entry_uom_so LIKE LINE OF lt_select_options,

lt_stg_loc TYPE TABLE OF /iwbep/s_cod_select_option,

ls_stg_loc LIKE LINE OF lt_stg_loc,

lt_batch TYPE TABLE OF /iwbep/s_cod_select_option,

ls_batch LIKE LINE OF lt_batch,

lt_reserv_no TYPE TABLE OF /iwbep/s_cod_select_option,

ls_reserv_no LIKE LINE OF lt_reserv_no,

lt_res_item TYPE TABLE OF /iwbep/s_cod_select_option,

ls_res_item LIKE LINE OF lt_res_item,

lt_entry_qnt TYPE TABLE OF /iwbep/s_cod_select_option,

ls_entry_qnt LIKE LINE OF lt_entry_qnt,

lt_entry_uom TYPE TABLE OF /iwbep/s_cod_select_option,

ls_entry_uom LIKE LINE OF lt_entry_uom,

ls_return TYPE bapiret1,

lt_goodsmovements TYPE TABLE OF bapi2017_gm_item_create,

ls_goodsmovements LIKE LINE OF lt_goodsmovements,

lv_reserv_lines TYPE int4,

lv_index TYPE int4 VALUE 1,

lt_detail_return TYPE TABLE OF bapi_coru_return,

ls_detail_return LIKE LINE OF lt_detail_return,

lv_log_handle TYPE balloghndl,

lv_message TYPE char200,

lo_logger TYPE REF TO zcl_bc_app_logger,

es_entityset LIKE LINE OF et_entityset,

lv_error_message TYPE bapi_msg,

ls_order_objects TYPE bapi_pi_order_objects,

lt_phase TYPE TABLE OF bapi_order_phase,

ls_phase LIKE LINE OF lt_phase,

lt_timetickets TYPE TABLE OF bapi_pi_timeticket1,

ls_timetickets LIKE LINE OF lt_timetickets,

lv_number TYPE bapi_order_key-order_number,

ls_op TYPE rcrop,

ls_vgw TYPE rcrvgw,

ls_afvc TYPE afvc,

ls_plpo TYPE plpo,

lv_value_fix TYPE p DECIMALS 4,

lv_value_var TYPE p DECIMALS 4,

lv_value TYPE p DECIMALS 4,

lv_unit TYPE rcrvgw-vge01,

lv_output TYPE p DECIMALS 3.

FIELD-SYMBOLS: <fs_timetickets> LIKE LINE OF lt_timetickets.

" create a log instance

CREATE OBJECT lo_logger

EXPORTING

iv_subobject = 'ZPP_APP'.

lo_logger->create_log( IMPORTING ev_log_handle = lv_log_handle ).

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = 'Begin Method PROCCONFIRMATION_GET_ENTITYSET.' ). " add custom message to message log

"get $filter through the io_tech request (odata request)

lt_filters = io_tech_request_context->get_filter( )->get_filter_select_options( ).

" Process filters

" for these below we just need the singular select option structure

READ TABLE lt_filters WITH TABLE KEY property = 'PLANT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_plant_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ORDERID' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_orderid_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'FIN_CONF' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_fin_conf_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'DEV_REASON' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_dev_reason_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'CONF_TEXT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_conf_text_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'CONF_QUAN_UNIT' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_conf_quan_unit_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'YIELD' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_yield_so INDEX 1.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'SCRAP' INTO ls_filters.

lt_select_options = ls_filters-select_options.

READ TABLE lt_select_options INTO ls_scrap_so INDEX 1.

" for the following we need tables (make a loop and get the values from each)

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'STGE_LOC' INTO ls_filters.

lt_stg_loc = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'BATCH' INTO ls_filters.

lt_batch = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'RESERV_NO' INTO ls_filters.

lt_reserv_no = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'RES_ITEM' INTO ls_filters.

lt_res_item = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ENTRY_QNT' INTO ls_filters.

lt_entry_qnt = ls_filters-select_options.

CLEAR ls_filters.

READ TABLE lt_filters WITH TABLE KEY property = 'ENTRY_UOM' INTO ls_filters.

lt_entry_uom = ls_filters-select_options.

" Create goodsmovement structure for all the retroactive items

DESCRIBE TABLE lt_reserv_no LINES lv_reserv_lines.

DO lv_reserv_lines TIMES.

ls_stg_loc = lt_stg_loc[ lv_index ].

ls_batch = lt_batch[ lv_index ].

ls_reserv_no = lt_reserv_no[ lv_index ].

ls_res_item = lt_res_item[ lv_index ].

ls_entry_qnt = lt_entry_qnt[ lv_index ].

ls_entry_uom = lt_entry_uom[ lv_index ].

ls_goodsmovements-plant = ls_plant_so-low. " fixed factory

ls_goodsmovements-stge_loc = ls_stg_loc-low.

ls_goodsmovements-batch = ls_batch-low.

ls_goodsmovements-move_type = '261'. " fixed movement type

ls_goodsmovements-item_text = 'Warenbewegung für Rückmeldung PP APP'.

ls_goodsmovements-reserv_no = ls_reserv_no-low.

ls_goodsmovements-res_item = ls_res_item-low.

ls_goodsmovements-entry_qnt = ls_entry_qnt-low.

ls_goodsmovements-entry_uom = ls_entry_uom-low.

APPEND ls_goodsmovements TO lt_goodsmovements.

lv_index = lv_index + 1.

ENDDO.

ls_order_objects-phases = 'X'.

lv_number = ls_orderid_so-low.

CALL FUNCTION 'BAPI_PROCORD_GET_DETAIL'

EXPORTING

number = lv_number

* COLLECTIVE_ORDER =

order_objects = ls_order_objects

* IMPORTING

* RETURN =

TABLES

* HEADER =

* POSITION =

* SEQUENCE =

phase = lt_phase

* TRIGGER_POINT =

* COMPONENT =

* PROD_REL_TOOL =

.

LOOP AT lt_phase INTO ls_phase. " for each phase - create both the activities table and timetickets table

CLEAR ls_timetickets.

" this is the full key for table AFVC - Auftragsarbeitsvorgang for the routing number and counter - should always work with SELECT SINGLE

SELECT SINGLE * FROM afvc INTO ls_afvc

WHERE aufpl = ls_phase-routing_no

AND aplzl = ls_phase-counter.

" this is the full key for table PLPO - Plan: Vorgang - so it should always work with SELECT SINGLE

SELECT SINGLE * FROM plpo INTO ls_plpo

WHERE plnty EQ ls_afvc-plnty

AND plnnr EQ ls_afvc-plnnr

AND plnkn EQ ls_afvc-plnkn

AND zaehl EQ ls_afvc-zaehl.

" now provide all the standard values (vorgabewert) VGW01, 02, etc into the calculation formula

MOVE-CORRESPONDING ls_plpo TO ls_op.

ls_op-mgvrg = ls_yield_so-low.

ls_op-meinh = ls_conf_quan_unit_so-low.

MOVE-CORRESPONDING ls_plpo TO ls_vgw.

DO 6 TIMES. " for each activity (usually 4 activities here at company, but there can be up to 6 activities total)

IF sy-index EQ 1 AND ls_vgw-vgw01 EQ 0

OR sy-index EQ 2 AND ls_vgw-vgw02 EQ 0

OR sy-index EQ 3 AND ls_vgw-vgw03 EQ 0

OR sy-index EQ 4 AND ls_vgw-vgw04 EQ 0

OR sy-index EQ 5 AND ls_vgw-vgw05 EQ 0

OR sy-index EQ 6 AND ls_vgw-vgw06 EQ 0.

CONTINUE. " skip and 0 values

ENDIF.

CALL FUNCTION 'CR_WORKCENTER_FORMULA_CALC' " You can see a SAP standard example with the function in the source code for transaction CR03 for costing formula: Program SAPLCRA0, Include LCRA0F71, Form FORMEL_RESULT_CALC, line 55

EXPORTING

arbid = ls_afvc-arbid

op = ls_op

vgw = ls_vgw

index = sy-index

date = sy-datum

IMPORTING

value_fix = lv_value_fix

value_var = lv_value_var

unit = lv_unit

EXCEPTIONS

missing_parameter = 1

not_found = 2

division_by_zero = 3

OTHERS = 4.

IF sy-subrc <> 0.

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

lv_value = lv_value_fix + lv_value_var. " total value is the sum of the fixed and varible values for this activity

" Convert any 'H' values to 'MIN'

IF lv_unit NE 'MIN'.

CALL FUNCTION 'UNIT_CONVERSION_SIMPLE'

EXPORTING

input = lv_value

unit_in = lv_unit

unit_out = 'MIN'

IMPORTING

output = lv_output

EXCEPTIONS

conversion_not_found = 1

division_by_zero = 2

input_invalid = 3

output_invalid = 4

overflow = 5

type_invalid = 6

units_missing = 7

unit_in_not_found = 8

unit_out_not_found = 9

OTHERS = 10.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

lv_unit = 'MIN'. " 2018.04.19 - need to overwrite unit to MIN!

ELSE.

lv_output = lv_value. " copy over MIN value

ENDIF.

CASE sy-index.

WHEN 1.

ls_timetickets-conf_activity1 = lv_output.

ls_timetickets-conf_acti_unit1 = 'MIN'.

WHEN 2.

ls_timetickets-conf_activity2 = lv_output.

ls_timetickets-conf_acti_unit2 = 'MIN'.

WHEN 3.

ls_timetickets-conf_activity3 = lv_output.

ls_timetickets-conf_acti_unit3 = 'MIN'.

WHEN 4.

ls_timetickets-conf_activity4 = lv_output.

ls_timetickets-conf_acti_unit4 = 'MIN'.

WHEN 5.

ls_timetickets-conf_activity5 = lv_output.

ls_timetickets-conf_acti_unit5 = 'MIN'.

WHEN 6.

ls_timetickets-conf_activity6 = lv_output.

ls_timetickets-conf_acti_unit6 = 'MIN'.

ENDCASE.

ENDDO.

" Also build the table to confirm the operations (Vorgänge)

ls_timetickets-conf_no = ls_phase-conf_no.

ls_timetickets-orderid = ls_orderid_so-low.

ls_timetickets-phase = ls_phase-operation_number.

ls_timetickets-resource = ls_phase-resource. " Resource in process orders is the equivalent of work_center (wrk_cntr) for production orders

ls_timetickets-plant = ls_plant_so-low.

ls_timetickets-logdate = sy-datlo.

ls_timetickets-logtime = sy-timlo.

ls_timetickets-postg_date = sy-datlo.

ls_timetickets-yield = ls_yield_so-low.

ls_timetickets-scrap = ls_scrap_so-low.

ls_timetickets-fin_conf = ls_fin_conf_so-low. " also overwrite the proposed tiel oder endruckmeldung - take what the user provides!

ls_timetickets-conf_quan_unit = ls_conf_quan_unit_so-low. " Also the unit

APPEND ls_timetickets TO lt_timetickets.

ENDLOOP.

CALL FUNCTION 'BAPI_PROCORDCONF_CREATE_TT'

* EXPORTING

* POST_WRONG_ENTRIES = '0'

* TESTRUN =

IMPORTING

return = ls_return

TABLES

timetickets = lt_timetickets

goodsmovements = lt_goodsmovements

* LINK_CONF_GOODSMOV =

* CHARACTERISTICS_WIPBATCH =

* LINK_CONF_CHAR_WIPBATCH =

* CHARACTERISTICS_BATCH =

* LINK_GM_CHAR_BATCH =

detail_return = lt_detail_return

EXCEPTIONS

OTHERS = 1.

IF sy-subrc <> 0.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = '' ). " add custom message to message log

CONCATENATE sy-msgno sy-msgid sy-msgv1 sy-msgv2 sy-msgv3 sy-msgv4 INTO es_entityset-error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

IF ls_return IS NOT INITIAL.

LOOP AT lt_detail_return INTO ls_detail_return WHERE type EQ 'E'.

lv_error_message = ls_detail_return-message.

ENDLOOP.

CONCATENATE 'Fehler bei der Rückmeldung: ' lv_error_message INTO lv_message.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = lv_message ). " add custom message to message log

es_entityset-error_message = lv_error_message.

APPEND es_entityset TO et_entityset.

ENDIF.

lo_logger->create_message( EXPORTING iv_log_handle = lv_log_handle iv_message = 'Ende Method PROCCONFIRMATION_GET_ENTITYSET.' ). " add custom message to message log

lo_logger->save_log( EXPORTING iv_log_handle = lv_log_handle ).

" FB Documentation says COMMIT WORK is required

CALL FUNCTION 'BAPI_TRANSACTION_COMMIT'

EXPORTING

wait = 'X'.

COMMIT WORK AND WAIT.

Final Comments

Whew. Did it feel like a marathon? :runner: Because it felt to me like a marathon all that time I was scratching my head. I hope you all enjoyed and found this post useful for a not-so-often programmed function of this production planning section of SAP.

Another note and quick plug 😊 I hope everyone can appreciate the time I put into creating these posts (hint: posts this long take a LONG time to write!). It would make me happy and give me the motivation to keep writing these detailed ABAP posts if you'd consider donating (in the footer of any page on this blog) I have a PayPal.me link, and I'm also an Ethereum developer if you'd like to donate Ether or if you would like to donate some RaiBlocks, as I am a RaiBlocks enthusiast if you would prefer to donate in that way.

:poop: Ok, plug done! :poop:

Cheers! 🍺

Footnotes

- Activities/phases are for production orders; Operations are for process orders. From this point onward, I will refer just to activities, since this post focuses on production orders. I also post the adjacent code for process orders in this post.

- I have to give credit where credit is due! I received a lot of assistance from our production planning module supervisor - he showed me the transactions that finally got me to a working result. :thumbsup:

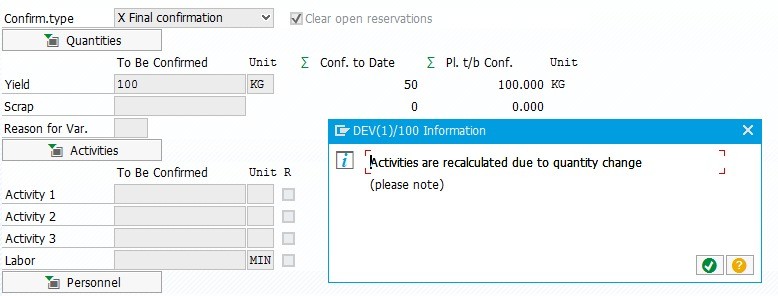

- You can set up your production planning (PP) module to give you a proposal amount for the activities, directly when you are doing confirmations transaction

CO11N:

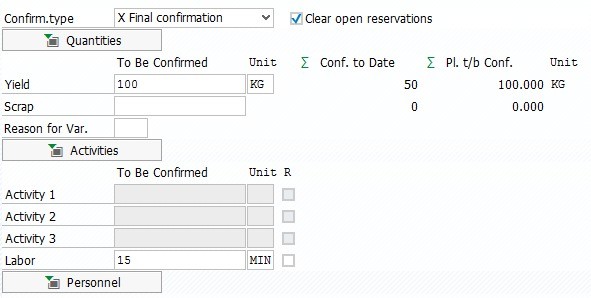

Upon pressing 'enter' for with a new amount:

Pressing 'OK' for this window, we get a popup:

We see that the Labor time is provided here. It's likely 30 min for a full 100 KG, since the system is proposing only 15 minutes for 50 KG, half of what the full order amount should be. (I know, it's not a full four field example - but values would also be proposed if you had more fields like machine time, machine set-up, etc.)

- Note: At my company, we usually use only up to four confirmation activities. Note that there can be up to six, but for this example, we'll say that the confirmation process has only a maximum of four.

- I ended up determining that you can exclude parameter

co_awithout any issues - however, this may be how the settings at my own company work - you can look deeper into the SAP example to include it.

- This issue does not affect the confirmation formulas, but rather the goods movements in the retrograde ingredients - specifically when the goods movements are to be overridden, for example with a batch split for a retrograde material, or a custom under- or over- amount of a retrograde material. For the rare case where an employee wanted to book some of our retrograde materials from various batch numbers and warehouse locations, they noticed in these custom goods movements with the confirmation were not being added; but rather always the default SAP-calculated amounts. After some head scratching, I found it all has to do with function module

BAPI_PRODORDCONF_CREATE_TT(orBAPI_PROCORDCONF_CREATE_TTdepending on your use case) - I was not passing in an important parameter which allows exactly this desired override behavior:

LinkConfGoodsmov The assignment of the goods movements to a confirmation is effected via the LinkConfGoodsmov table. There must be an entry in this table for every entry in the Goodsmovements table. The index in the LinkConfGoodsmov-Index_Confirm field refers to the line of the associated confirmation in the Timetickets table and the index in the LinkConfGoodsmov-Index_Goodsmov field refers the associated goods movement in the Goodsmovements table. If you want to prevent a goods movement from being posted for a confirmation according to the standard logic, make an entry in the LinkConfGoodsmov table as well as in the Timetickets table. The index in the LinkConfGoodsmov-Index_Confirm field refers to the line of the associated confirmation in the Timetickets table. Enter the initial value 0 in the LinkConfGoodsmov-Index_Goodsmov field. It is not necessary to make an entry in the Goodsmovements table in this case. If there is no entry in the LinkConfGoodsmov table for a confirmation, goods movements are determined for backflushing and automatic goods receipt using the standard logic.

We needed to add the following too our goods movements loop (already added in the code above! 😊):

BLAH